Tension gas springs, also known as tension gas struts or tension gas shocks, are mechanical devices that harness the power of compressed gas to generate controlled force in a linear motion. These springs have found diverse applications across industries, from automotive engineering to furniture design. This article delves into the mechanics behind tension gas spring, their components, working principles, and various applications that highlight their significance.

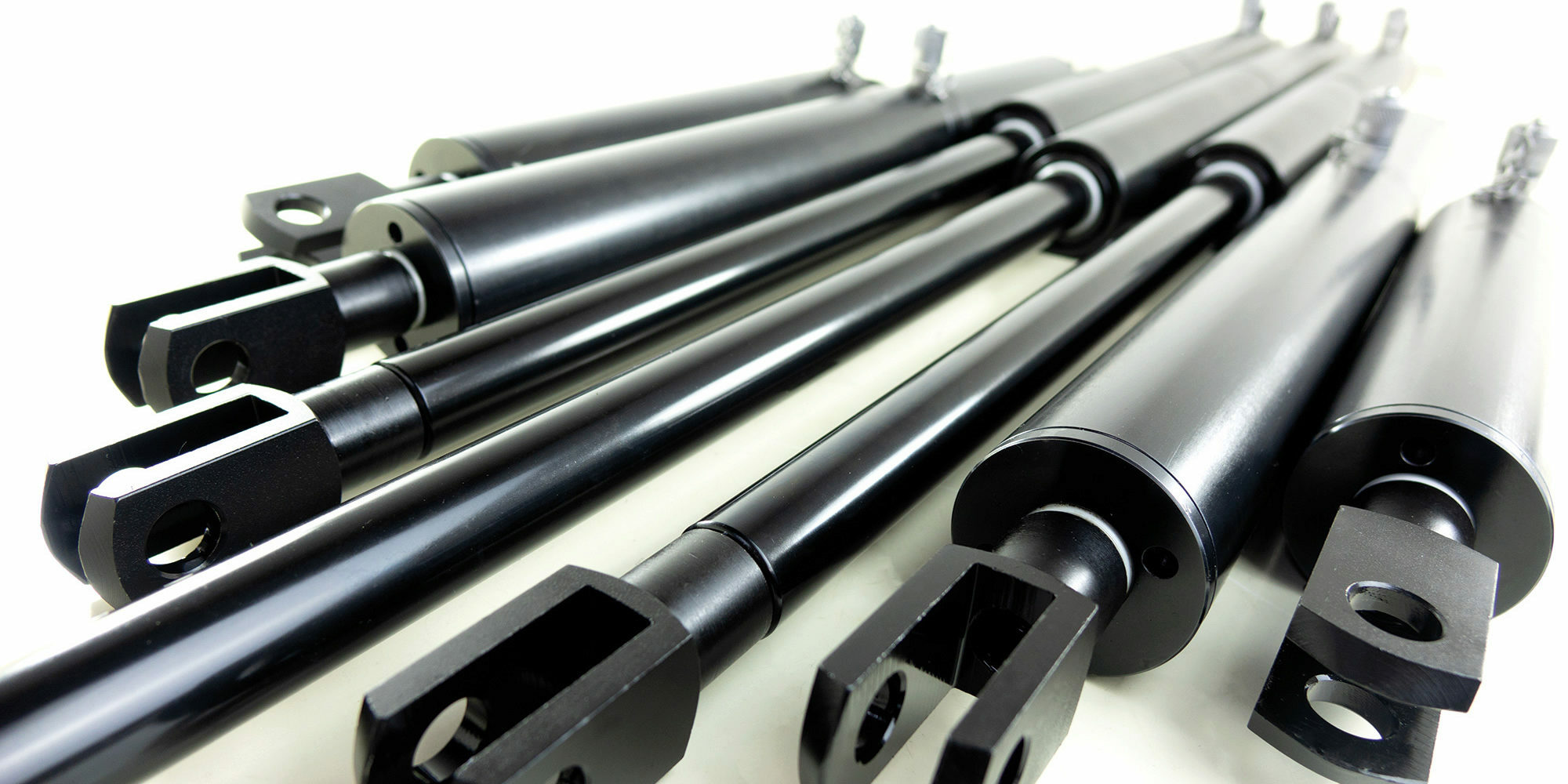

Mechanics and Components: Tension gas springs consist of a few key components that work together to generate force. The primary components include:

Cylinder: A sealed cylinder, usually made of metal, houses the gas and serves as the primary structural component.

Piston: Inside the cylinder, a piston separates the gas from the oil, preventing them from mixing. The piston is designed to move linearly within the cylinder.

Gas Charge: The cylinder contains a predetermined quantity of compressed gas, usually nitrogen, which provides the tension or force when the spring is activated.

Oil: A small amount of oil is placed inside the cylinder below the piston to control the motion and damping characteristics of the spring.

End Fittings: These are the attachments at either end of the spring that connect it to the surfaces or objects it is meant to act upon.

Working Principles: When a force is applied to the tension gas spring, it compresses, causing the piston to move against the gas charge and the oil resistance. The gas pressure builds up, creating tension or force that opposes the applied force. As the spring extends, the gas pressure decreases, and the oil dampens the motion, resulting in controlled and smooth movement.

The tension gas spring operates according to Hooke's law, which states that the force exerted by a spring is directly proportional to the displacement it undergoes. This linear relationship makes tension gas springs ideal for applications where controlled force and motion are required.

Applications: Tension gas springs find a wide range of applications due to their unique characteristics. Some notable applications include:

Automotive Industry: Tension gas springs are commonly used in automotive applications, such as trunk lids, hoods, and tailgates. They provide controlled opening and closing motions, enhancing user convenience and safety.

Furniture Design: In furniture design, tension gas springs are utilized to create adjustable and ergonomic pieces. Chairs with adjustable heights, recliners, and foldable tables often incorporate these springs to facilitate smooth adjustments.

Medical Equipment: Tension gas springs play a vital role in medical equipment design, including hospital beds, surgical tables, and diagnostic equipment. They enable precise positioning and adjustments, contributing to improved patient care.

Aerospace: In aerospace engineering, tension gas springs are used in mechanisms like landing gear systems and cargo doors, ensuring controlled movements and reliable operations.

Industrial Machinery: Tension gas springs find applications in industrial machinery where controlled motion, such as lifting and lowering heavy loads, is crucial. They also help dampen vibrations and shocks in various industrial setups.

Marine Industry: Marine vessels utilize tension gas springs for hatch openings, compartment doors, and other access points. The springs ensure secure and controlled movement in challenging maritime conditions.

Advantages and Considerations: Tension gas springs offer several advantages, including:

Smooth Motion: Tension gas springs provide controlled and smooth linear motion, enhancing user experience and reducing wear and tear on mechanisms.

Adjustability: Their linear force-displacement relationship allows for precise adjustments, making them suitable for applications requiring accurate positioning.

Safety: Tension gas springs help prevent sudden movements, reducing the risk of accidents and injuries.

However, there are some considerations to bear in mind:

Temperature Sensitivity: Extreme temperatures can affect the performance of tension gas springs, causing variations in pressure and behavior.

Wear and Tear: Over time, gas leaks or changes in oil viscosity can impact the spring's performance. Regular maintenance is essential to ensure consistent operation.

Conclusion: Tension gas springs are versatile mechanical devices that harness compressed gas to provide controlled linear force. Their applications span across numerous industries, from automotive to aerospace, offering benefits such as smooth motion, adjustability, and safety. As technology continues to advance, tension gas springs will likely see further refinement and expanded applications, contributing to more efficient and ergonomic designs across various fields.