FULL DISCLOSURE: This editorial is commercially slanted. It both advertises for a company, as well as its products and services. Reasonable blasting information is also provided in the editorial.

SMALL THINGS IN BLASTING MAKE ALL THE DIFFERENCE

first Published: Quarry February 2011

Within the blasting process, the areas that can be optimised and improved are small and easy to dismiss. Brent Buffham explains why quarry operators should take extra notice of the little things.

There aren’t too many places left within the blasting process that haven’t been investigated to the nth degree. The optimisation and economics of blasting and the downstream processes directly affected by poor or uneconomic blasting practices have become areas of importance. The unsettling fact that many drilling and blasting contractors and clients of blasting services realise the main areas that can be optimised, however, generally does not enact their knowledge. In a world that has the “continuous improvement” mindset, we must ask ourselves: “How much is actually being improved?” More importantly, we should also be asking: “How is it being monitored and implemented?” Blast results are the responsibility of every process from initial resource planning to the final excavation of the blast muck pile. These can be segregated into simplified categories, including preparation, design, implementation, drilling, priming, loading, stemming, timing, firing and extraction. The above categories are areas in which Maxam endeavours to assist its clients. We can all understand that in order to achieve a professional job, eg pouring a house pad, the preparation must be excellent. This is also true in blasting. Achieving great blast results with poor preparation is difficult. Bench preparation in terms of sheeting, access for equipment and personnel must be adequate with the preference of excellence. Preparation should also consider the successive processes so that the good intention can be realised.

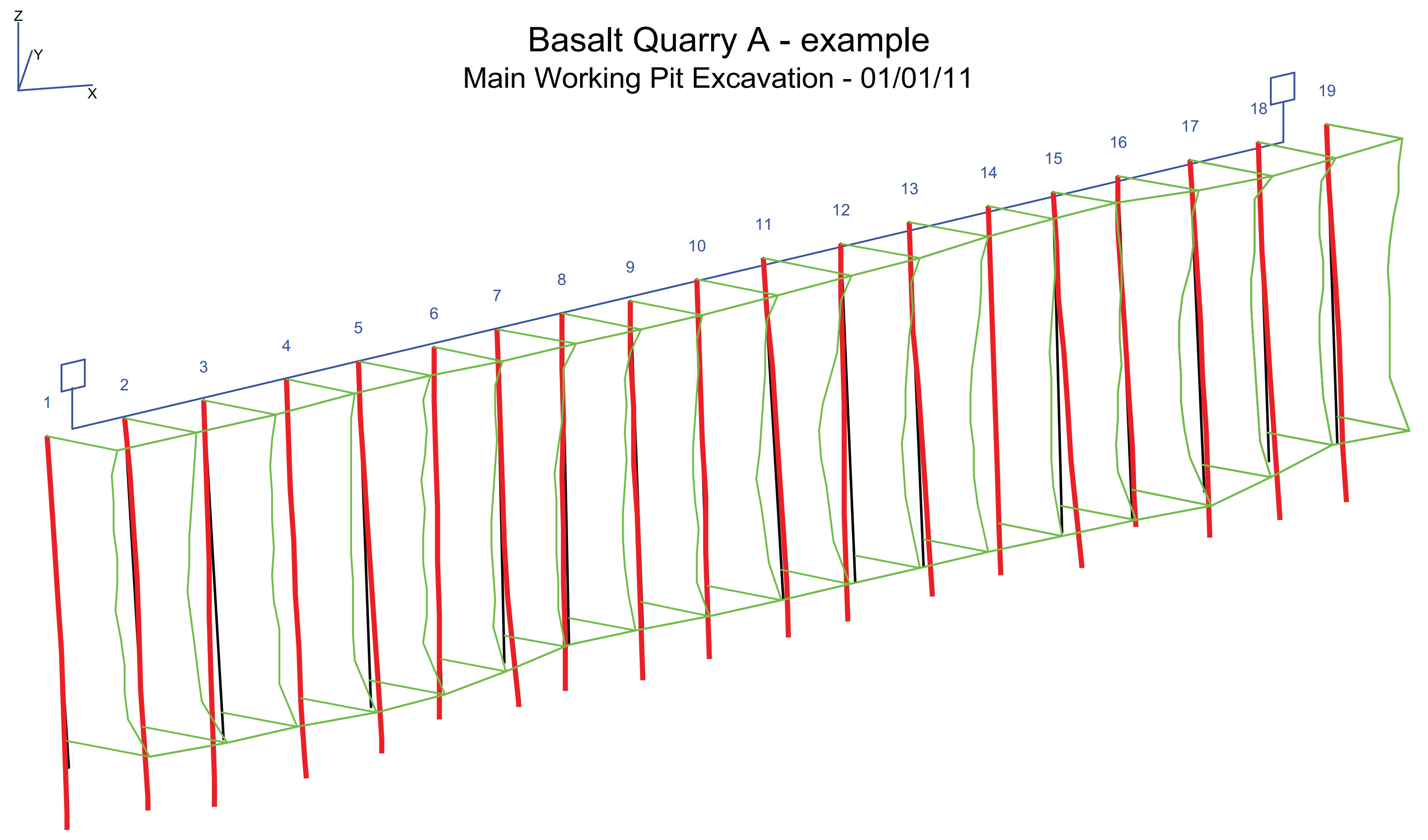

Figure 1. An isometric profile of bore tracks in a basalt quarry.

MAKE OR BREAK DESIGN

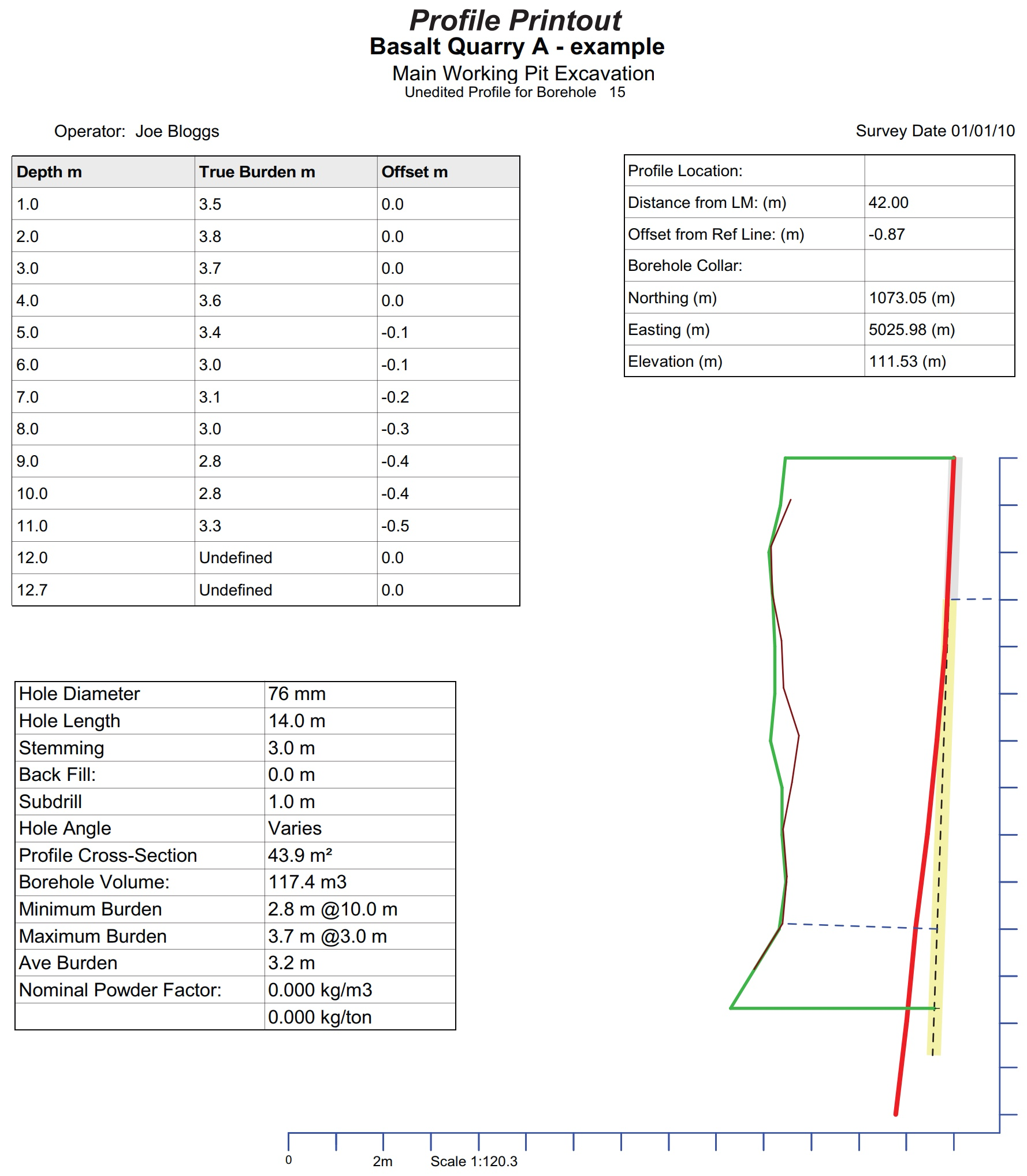

Design plays a crucial part in blasting, as we all know. It is an essential attribute of the blasting process that can make or break the best intentions. Not paying attention to concerning conditions that present can lead to inadequacies in the distribution of explosion energy and thus poor blast results. Maxam maintains site-specific parameter sets for all total service sites, allowing its technical service team to provide clients with insight into what has been and what may result should optimisations be trailed. The key attributes of Maxam’s total service are laser profiling and bore tracking (Figures 1 and 2). These two alone can vastly Improve site economics and blast results, like fragmentation, throw, toe movement, powder factor, confinement, environmental compliance and more. With all processes in our modern era, we must concern ourselves with safety and how it affects us. The implementation must be considered in terms of three aspects:

Necessity.

Adequacy.

Safety.

If the above are unanswerable, we must ask ourselves why we are implementing them. To be confident with the expectations of results and downstream effects, our actions require reasons for their implementation.

Figure 2. A profile printout of 15 boreholes in a basalt quarry.

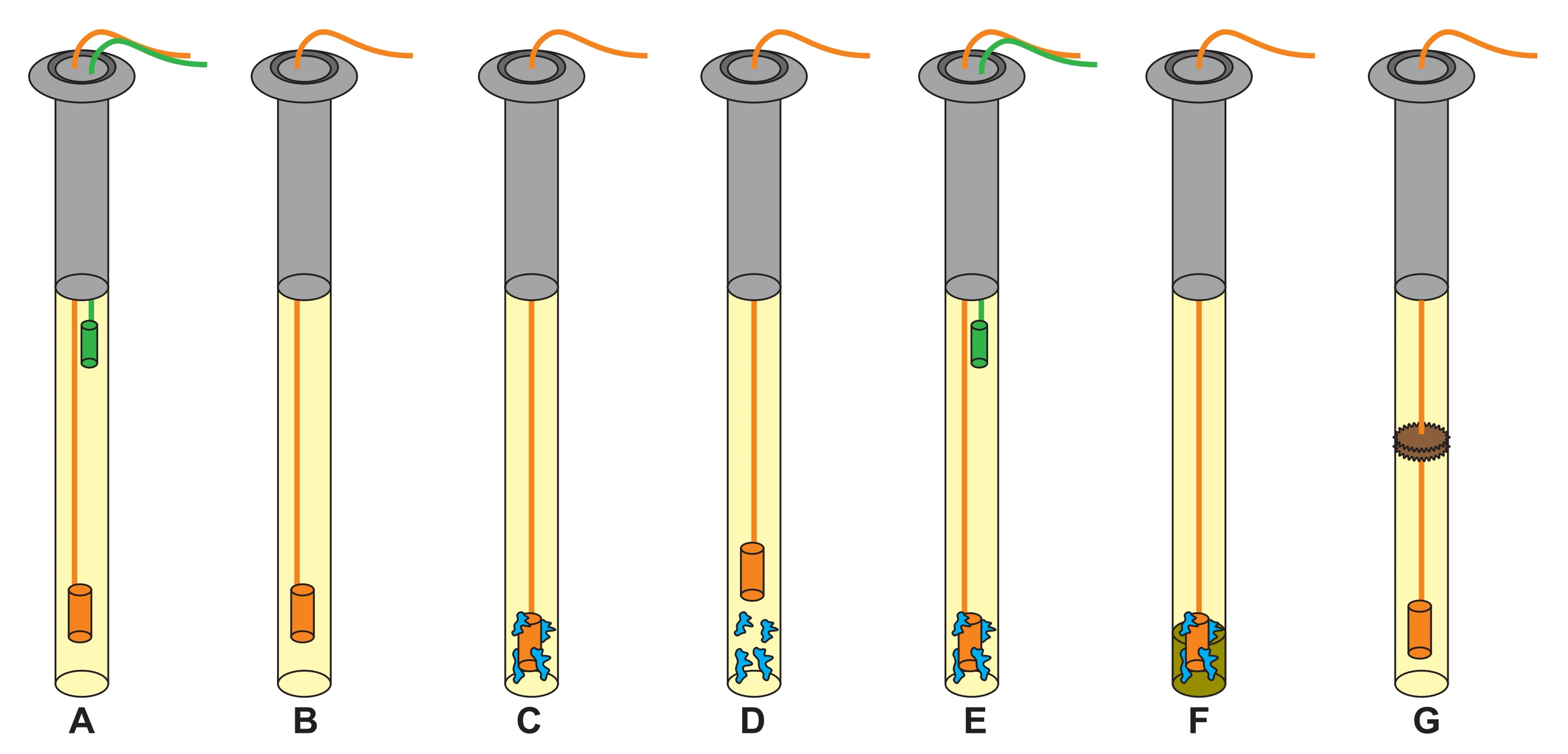

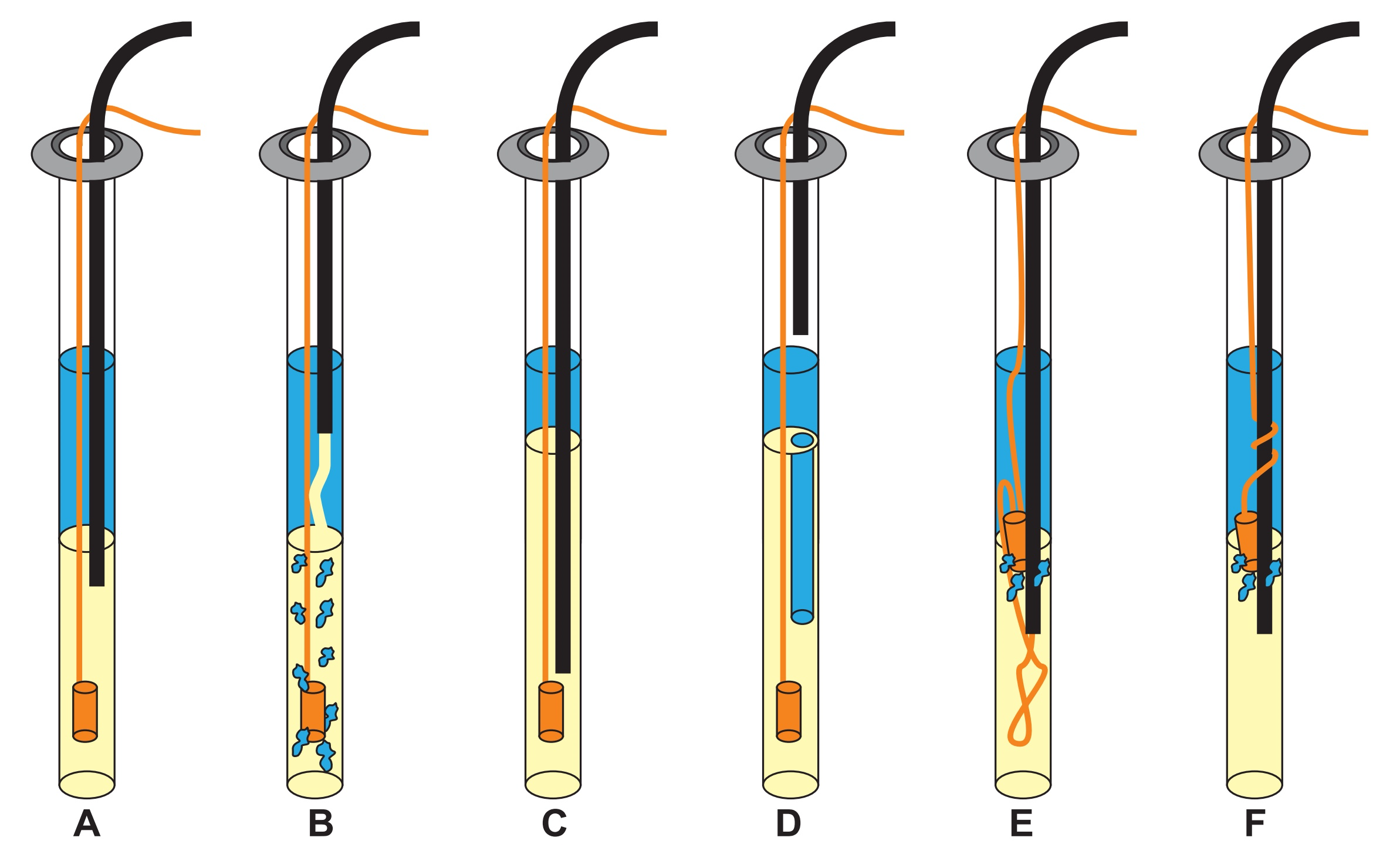

PRIMING AND LOADING

Drilling and drillers are vital purveyors of information that cannot be gleaned from any other process. To underplay the importance of drilling is to expect poor results. Maxam has the ability to provide many forms of “drill log recording” tools. These tools, when utilised, can determine the further actions required to turn potential poor results into good, even excellent, results. It is the small things that make the difference in blasting, and a contributing factor for product columns being discovered in the blasted muck piles is inadequate priming. Priming practices (Figure 3) such as “pulling” the priming unit into a competent product is vital with pumpable product ranges such as Maxam’s RIOFLEX 10000 bulk product. Loading practices (Figure 4) are aspects that are sometimes not focused upon; this produces an air of confusion amongst clients and operators. It is not acceptable practice to just “stick it in the hole”; loading is a skill that impacts on blast results. Maxam’s RIOFLEX range is robust and reliable in the harshest conditions but, sooner or later, poor loading will break the safeguards that Maxam’s stringent manufacturing protocols have put in place. Stemming is often considered to be one of the least important aspects of the blasting process, more so in the mining industry where environmental concerns are often reduced. However, what type of stemming and how the practice is conducted can make the difference. Various stemming types can be used and each has its appropriate reason but the best stemming is considered to be crushed angular rock, around 10 to 14 per cent of the hole diameter. The speed of stemming practices can greatly affect the performance of containment. It is important to ensure the stemming is placed in the hole with enough time to settle without bridging. Go too fast and you can expect ejection and loss of explosion energy. Stemming can also add value to your blast; the right stemming can reduce powder factors, increase containment, reduce environmental readings and increase fragmentation, all of which have flow-on economic improvements that cannot be ignored. Timing can assist with blast performance and requires due attention. Not too much difference is made if the previous steps have been poorly implemented. Timing compliments the results when correctly applied in conjunction with the other blast-related aspects if correctly implemented. Most importantly, timing is about relief! How much you allow the blast to utilise your design is entirely in timing’s realm of control, thus yours. Maxam utilises computer-aided simulations to provide the best advice.

Figure 3. The priming of blast holes is integral in successful blasting.

Description of Figure 3 issues related to the priming of blast holes.

(A) Optimal bottom and top primed blast hole.

(B) Optimal bottom primed blast hole.

(C) Priming unit in the decoupled product - possible deflagration.

(D) Priming unit is “pulled” into the competent product - full order detonation.

(E) Bottom priming unit in decoupled product with top priming unit in the competent product - low to full order detonation.

(F) Priming unit partially embedded in silt or a “snagged” priming unit - deflagration to low order detonation.

(G) Inert material separating the product column - partial product column detonation and misfire.

Figure 4. Clients and operators can be easily confused if loading practices are not given due attention.

Description of Figure 4 Issues related to the loading of blast holes.

(A) Optimal hose retraction - hose 300mm in product at all times.

(B) Hose retraction speed too fast - deflagration to low order detonation of the decoupled product column.

(C) Hose retraction speed too slow - inadequate explosive amount, hose placement effectively reduces the diameter of the blast hole.

(D) Result of figure “C” - foreign material is “sucked” into the product column, decoupling occurs - possible low order detonation.

(E) Floating primer – down line has some tension, as it is suspended in product - misleading interpretation of correct loading - deflagration to low order detonation.

(F) Tangled lead on hose due to slack lead on loading commencement or large diameter blast holes - deflagration to low order detonation.

SAFETY FACTORS

Firing your blast is about safety. Simply put, if we conduct an effective blast but destroy or harm equipment or personnel, the result is forfeited. Maxam’s logistic service vehicles and blast utilities all have sirens to assist with pit clearance runs. Maxam can draft clearance procedures for your site with industry best practices in mind via our expert occupational health and safety team. Quarry operators can improve their blasting in cost-effective ways, eg reduced level markers on active benches to help with “digging to grade” is just one way. Maxam can implement RL markers specific to your site and with these in place, spot check floor levels, bench levels and crest lines. The Maxam team can make a difference with advice on the small things, ie the areas for the greatest gains via optimisation and continuous improvement. Every small improvement or little correction to practices and application of products and services can and will improve your operation economically, productively and safely. In conjunction with Maxam’s reliable and expert team, the big problems are almost small themselves.

At the time of writing in 2011, Brent Buffham was the technical liaison officer for Maxam Australia.

FULL DISCLOSURE: The Editorial is commercially slanted to both advertise for a Companies products and Services as well as provide information.